Environmental Management

Commitment, Challenge and Opportunity

CH. Karnchang’s core operations, particularly its construction projects, have significant environmental impacts, including resource consumption, air and water pollution, and industrial waste management challenges.

These activities affect multiple stakeholders, including local communities around project sites, business partners, contractors, customers, and shareholders, all of whom are concerned with the company’s environmental and social sustainability. If not properly managed, these impacts could pose risks to operations, such as regulatory penalties or a decline in stakeholder confidence.

To address these challenges, CH. Karnchang has implemented environmental and sustainability policies committed to minimizing the pollution, resources, waste, and water impacts of its construction projects. This includes developing operational plans to mitigate effects on local communities and the environment while conducting ongoing impact assessments through external agencies. The company also prioritizes air pollution emission, water use and reduction, resource efficiency and responsible waste management—not only to reduce environmental harm but also to meet the growing demand for socially and environmentally responsible business practices. Furthermore, its commitment to sustainability enhances long-term business stability and strengthens stakeholder trust across all sectors.

Supporting the SDGs Goals

Goal 8:

Goal 12:

Stakeholders Directly Impacted

Goals and Performance Highlights

-

The amount of recycled waste is equivalent to 295 tons of carbon dioxide.

Base Year 2023

-

Reducing Waste and Scrap Materials Through Landfilling

Base Year 2023

- Reducing greenhouse gas emissions by the equivalent of 361 tons of carbon dioxide.

- This represents an increase of 66 tons of carbon dioxide equivalent compared to last year, or a 22.37% increase from the base year.

Management and Operational Approach

Environmental Management Process

CH. Karnchang manages environmental sustainability by adhering to policies on environmental management, green construction, climate responsibility, and biodiversity conservation.

These principles are integrated into every stage of the construction process—from planning and project execution to waste management and post-construction sustainability. The company follows ISO 9001:2015 standards for environmental management, requiring project management teams to develop operational plans and impact mitigation strategies for local communities and the environment. Continuous quality monitoring is conducted, with third-party organizations assessing and reporting environmental impacts in compliance with project owner requirements throughout the construction phase. This ensures transparency and accuracy for all stakeholders.

The company strictly monitors and reports compliance with environmental impact mitigation measures in each project. This includes air quality control through dust suppression techniques, noise and vibration monitoring, surface water quality assessments, and aquatic ecosystem protection. Hazardous waste and debris management is carefully planned, while transportation and traffic conditions are also monitored. Additionally, CH. Karnchang actively engages with local communities to address concerns and gather feedback on potential environmental impacts.

Beyond compliance, the company fosters environmental awareness by educating employees, contractors, customers, and business partners on resource conservation, waste management, and relevant environmental regulations. This collaborative approach supports long-term, sustainable, and responsible business operations.

CH. Karnchang has also formed a committee for safety, occupational health, and environmental management. This committee keeps environmental law databases up to date and aligned with business operations, conducts scheduled internal audits to ensure regulatory compliance, and holds annual meetings to review progress, address challenges, and propose continuous improvements for sustainability initiatives.

Social Responsibility and Sustainability Committee

The Social Responsibility and Sustainability Committee of CH. Karnchang Public Company Limited has appointed three members to oversee the company’s sustainability initiatives. Their key responsibilities include:

- Developing and proposing social and environmental policies for approval by the Board of Directors.

- Reviewing and endorsing the company’s CSR strategies to ensure alignment with sustainability goals. Evaluating and approving the annual CSR plan and budget before submission to the Executive Committee and Board of Directors.

- Monitoring CSR activities, assessing their progress and effectiveness, and evaluating the overall impact and quality of CSR initiatives.

- Carrying out additional responsibilities as assigned by the Board of Directors.

- Promoting sustainable business development by establishing policies that foster long-term growth while maximizing benefits for all stakeholders. This is achieved through adherence to environmental, social, and governance (ESG) principles and a commitment to measurable, impactful sustainability.

Water Management

Effective water management in construction is a crucial factor that requires careful planning, as water is a valuable resource with significant environmental impacts. Proper management can reduce costs, improve efficiency, and promote environmental sustainability.

For construction-related water use, thorough planning should be conducted from the project's outset. This includes estimating water requirements at each stage, from foundation work and concrete mixing to curing and site cleaning. It is also essential to consider water sources, which may include municipal water supplies, groundwater, or local natural sources. In most cases, the company primarily relies on water provided by the Metropolitan Waterworks Authority and the Provincial Waterworks Authority.

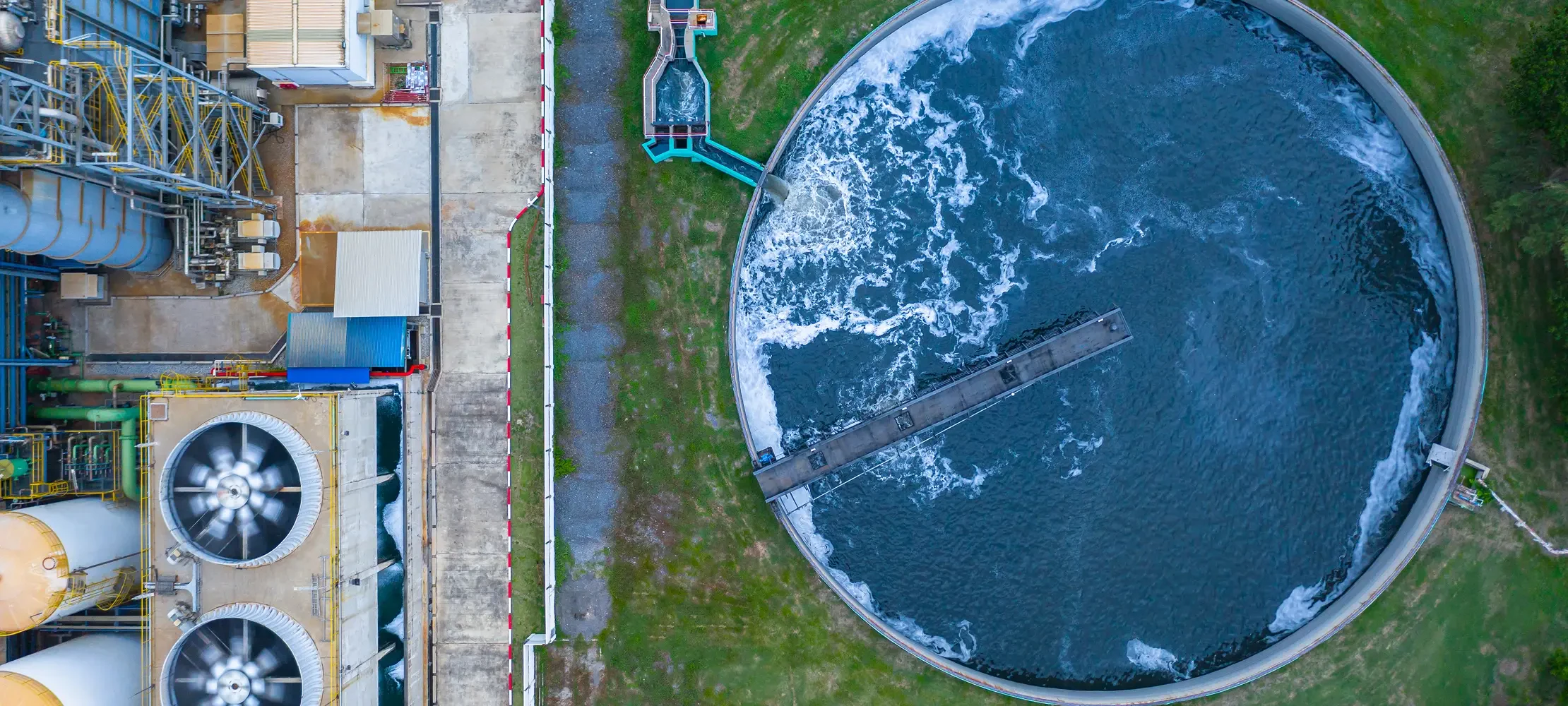

In terms of wastewater treatment, appropriate systems must be in place. Water recycling is a key component of sustainable water management, and the company actively promotes its implementation within projects. Treated water can be repurposed for activities that do not require high water quality, such as irrigation, surface cleaning, and dust control, thereby reducing the demand for clean water. Construction activities also generate contaminated water, such as wastewater from washing concrete mixing equipment and site cleaning. To address this, the company has implemented a system to separate stormwater drainage from wastewater. Sedimentation tanks and septic tanks are used to filter contaminants before releasing water into the public drainage system. Additionally, the company emphasizes wastewater management for both construction processes and temporary sanitation facilities.

Lastly, educating construction workers on efficient water use and conservation is a priority. Training programs, clear guidelines, and regular monitoring ensure that water management practices in construction projects remain effective and sustainable.

Water Monitoring and Risk Management in Construction Projects

Water accumulation within construction sites poses potential risks to structural integrity, disrupts project timelines, and leads to increased operational expenditures. To proactively mitigate these challenges, the company has implemented a comprehensive water management and drainage strategy aimed at minimizing risks at their source. A systematic approach has been established to continuously monitor and assess water levels, ensuring prompt intervention should water volumes exceed acceptable thresholds. This initiative aligns with best practices in risk mitigation, supports sustainable project management, and fulfills stakeholder expectations. The overarching principles guiding this framework are as follows:

Waste Management

The Luang Prabang Hydropower Project recognizes the importance of effective waste management in its operations, including leftover materials from construction, renovation, and demolition activities.

As the project's population grows, the amount of waste generated also increases. Without proper management in compliance with environmental regulations, this waste could have a significant impact on the environment and surrounding communities. Poor waste management can not only affect the landscape but also lead to soil and water contamination and pose safety risks to nearby residents. To address this, the company prioritizes a comprehensive waste management process, from initial planning to project completion. Waste is first sorted into two main categories: construction waste and community waste. Further classification is carried out to ensure proper disposal, as follows:

carried out to ensure proper disposal

- Non-hazardous, non-recyclable, non-combustible waste

- Non-hazardous, non-recyclable, combustible waste

- Non-hazardous organic waste, such as food scraps and vegetable waste

- Non-hazardous, recyclable, or reusable waste

- Hazardous waste, including engine oil, lubricants, grease, solvents, and batteries

- Hazardous infectious waste

Additionally, recyclable and reusable materials are sorted to minimize the amount of waste requiring disposal. Any remaining waste is sent to municipal authorities for proper processing.

The company has implemented waste management policies across all projects to ensure that waste handling in CH. Karnchang construction projects meets legal standards and best practices. This includes tracking the types, quantities, and weights of waste generated from construction activities—such as soil, sand, and materials from construction or demolition. The company also evaluates efficiency and addresses related issues by regularly inspecting construction sites for leftover waste and debris, with weekly progress checks conducted throughout the construction phase. Furthermore, employees are encouraged to recognize the importance of proper waste separation, supporting sustainable waste management efforts.

Incorporating Resource Efficiency into Construction Design

Sustainable construction requires careful planning to minimize resource consumption from the design stage. Several strategies can help achieve this goal:

- Efficient structural design starts with choosing an appropriate system, such as a post-tensioned structure, which allows for a thinner slab, reducing the use of concrete and rebar. Additionally, optimizing column spacing can help minimize the number of foundations and columns, improving overall efficiency.

- Using environmentally friendly alternative materials, such as fly ash to partially replace cement, not only reduces cement consumption but also enhances the quality of concrete.

- The use of technology in structural design and analysis enables precise simulation and evaluation of material usage, reducing errors and minimizing material waste during construction. Additionally, modern structural analysis software enhances the design process by optimizing material efficiency.

Construction methods designed for both building and dismantling should prioritize the use of precast systems, which help minimize on-site material waste and allow components to be reused when a building is demolished. Alternatively, implementing a Design for Deconstruction (DfD) approach enables materials to be repurposed in the future. To further reduce waste, designers should consider the standard sizes of commercially available materials and align their designs accordingly. This reduces excess material from cutting and leftover scraps. For example, column span lengths should match the standard dimensions of structural steel, and wall heights should be designed to fit available sheet materials.

The selection and design of construction materials should consider lifespan and maintenance. Choosing durable materials with a long service life and minimal maintenance needs helps reduce long-term material replacement. For example, using rust-resistant materials for steel structures in areas prone to corrosion during concrete pouring.

However, all operations must adhere to safety principles and relevant design standards. Proper evaluation and testing are required to ensure that material reduction does not compromise the structural integrity.

Air Pollution Management

During construction, total suspended particulates (TSP) and fine particulate matter (PM10) are key air pollutants that must be properly managed to minimize environmental and community impacts.

CH. Karnchang has implemented effective dust control measures to mitigate the effects of construction, renovation, repair, and demolition activities, which often release airborne dust. These measures help maintain air quality in nearby areas and reduce potential health risks for workers and surrounding communities.

Measures for controlling and reducing particulate matter emissions from construction activities

Work with the project owner to ensure compliance with relevant laws, regulations, and best practices for dust control in construction, including the National Environmental Quality Act of 1992, Bangkok city regulations, and the Pollution Control Department’s guidelines on managing construction dust.

Installing a water spray system at the construction site to control dust.

Lightly spray water over areas with exposed soil, as well as soil and sand piles, to reduce airborne dust.

Clean the vehicle and its wheels to remove any dirt, mud, or sand before taking it outside the construction site.

Limit vehicle speed in construction zones to minimize airborne dust.

Establish guidelines for dust control in construction, identify air quality monitoring points, and strictly adhere to plans and procedures in accordance with government-set standards.

CH. Karnchang continuously monitors and assesses air quality by measuring the 24-hour average of total suspended particulates (TSP) and particulate matter smaller than 10 microns (PM10) using a High Volume Air Sampler. Additionally, levels of nitrogen dioxide (NO₂) and sulfur dioxide (SO₂) are monitored to ensure air quality remains within regulatory standards. Additionally, CH. Karnchang has implemented a strategy to manage construction-related dust issues by setting up air quality monitoring points throughout the project site. The company also defines the project boundary, work plans, and operational procedures in compliance with government-mandated environmental standards.